Jingwei Brand Model Jwf1580 Serial Over-Prolongation Intelligent Ring Spinning Frame Smart Textile Machine JWF1580

Product Category:

Key words:

Email:

TEL:

Jingwei Brand Model Jwf1580 Serial Over-Prolongation Intelligent Ring Spinning Frame Smart Textile Machine JWF1580

Based on JWF1566 and JWF1582, JWF 1580 serial over-prolongation intelligent ring spinning frame, a new generation basic machine which is leading the development trends with its entire performances reaching international advanced level,integrates quick-installing technology, quick-doffing technology, dual-suctioning technology at both head stock and tail stock, and intelligent spinning expert system. lts energy consumption is reduced by 10% comparing to the current ring frames. JWF 1580 is an ideal choice for media- and high- end customers.

Precise head transmition --High quality yarn base

New type of high precision frame--One-piece central

wallboard, new type of anti-deformation and high

precision rail, pin hole positioning, zero adjustment and

fast installation, high speed guarantee.

Jingwei quality products without mechanical wave roller --High quality yarn guarantee

Oil bath lubrication, permanently stable tail shaft structure (patent technology)-Durable, least maintenance costs.

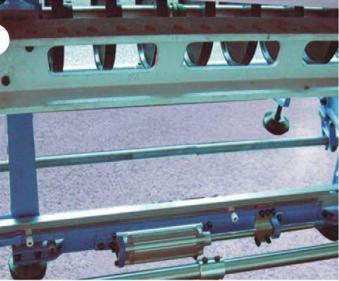

New tray conveying mechanism(patent technology)-Auto-doffng process efficiently.

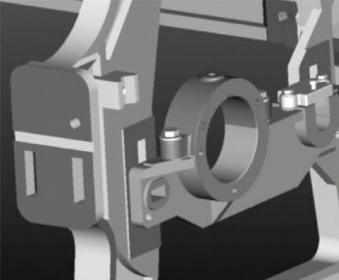

New gas holder internal and external cycloidal units-The core of automatic doffing.

Rapid doffing technology -Effectively improve the operation efficiency and output.

Automatic bobbin readying unit (patent technology)-Labor saving and effort saving guarantee.

Three roller compact spinning system/four roller compact spinning system.

Pin hole positioning technology--Precise installation, shorten the installation time.

★ Use the spindle and roller separation transmision technology, guarantee synchronous transmision of spindle and roller with the encoder tracking technology to effectively increase the yarn reserving rate.

★ Using high-precision servo system to control roller transmission, and guarantee the roller transmission synchronicity with pulse following technology,

★ Simple and convenient textile process adjustment

★ Display screen adopts fat and graphic display technology, simplified operation, and enhanced efficiency.

★ No modification required to realize the function of spinning bunchy yarn (embedded software, optional)

★ Individual spindle broken-end detection (optional) to reduce the labor intensity of machinists.

|

Spindle gauge |

70 |

|

Spindle number |

from 1248-1824,expanded by unit 36 spindles each |

|

Roller |

27X27X27or27X30X27 box length 6spindles |

|

Lift |

160,180(with aluminum spindle) |

|

Ring diameter mm |

38,40,42,45(PG type) |

|

Suitable for fiber length |

less than 40mm,40-51mm,51-60mm |

|

Suitable for yarn density Tex(Ne) |

36.4-4.86(16-120) |

|

Suitable for Twist ( turns per meter ) |

230-3000 ( Wharf diameter 19) |

|

Twist direetion |

Z with single tension disc, Z and S with dual tension disc |

|

Draft |

total draft 10-60(standard), total draft 10-80 (optional) |

|

Spindle speed r/min |

12000-25000(mechanical speed with inverter) |

|

Spindle driving |

driving by disc |

|

Drafting type |

3-line roller,cradle apron(short) plus bottom apron (long), top weighting arm |

|

Lifting type of ring plate |

by electronic lifting |

|

Twisting type |

by electronic twisting |

|

Doffing type |

auto-doffing |

|

Bobbin lifting rate when doffing |

>99.5% |

|

Tube inserting rate |

100% |

|

None-end break rate when auto-doffing finished |

>97% ( for medium count yarn ) |

|

Auto-doffing duration |

3 minutes |

Related Products

Please enter your message and we will contact you as soon as possible!

Yang: +8613583287688

Lulu Qin: +8615215328939

David: +8618866266827

Wei Hailei: +8618866227726

LESLIE: +8615705424292

William: +8617685722177

Qingdao Hongda

ADD: No. 17 Shenzhen Rd,Hi-tech Park Qingdao City, Shandong Province

TEL: 86-0532-84963219

E-MAIL: qdluluqin@163.com

NOTE: All quotations will be subject to CTMTC's final confirmation.

Copyright © 2022 Qingdao Hongda